Studies

Chimerical Technology have trained engineers and technician to perform studies and assist clients in developing projects.

We have a range of laboratory and pilot test equipment to get the most out of the project development phases.

1

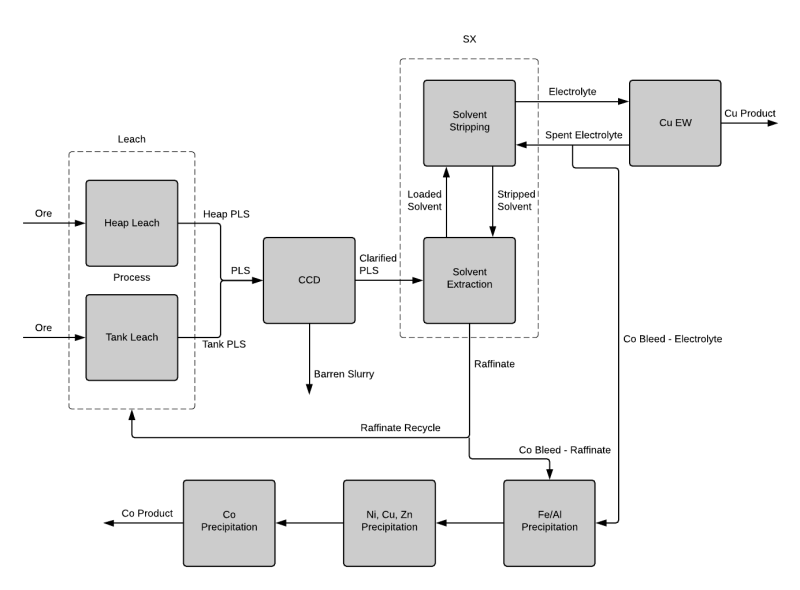

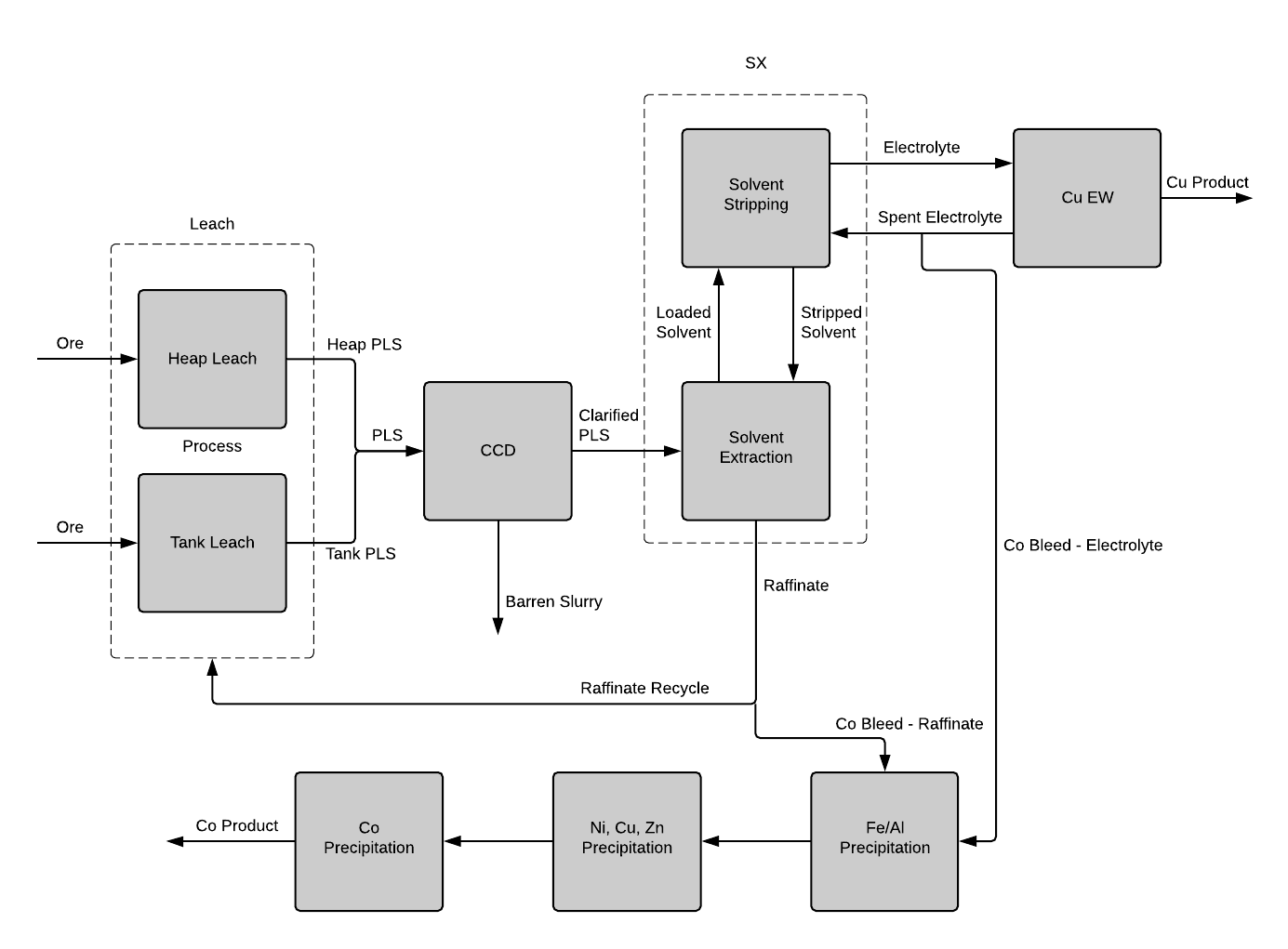

FEASIBILITY STUDY

Identify the key performance parameters and cost drivers for initial economic evaluation. Process simulations and case study data provide insight into expected system sizing and costs.

2

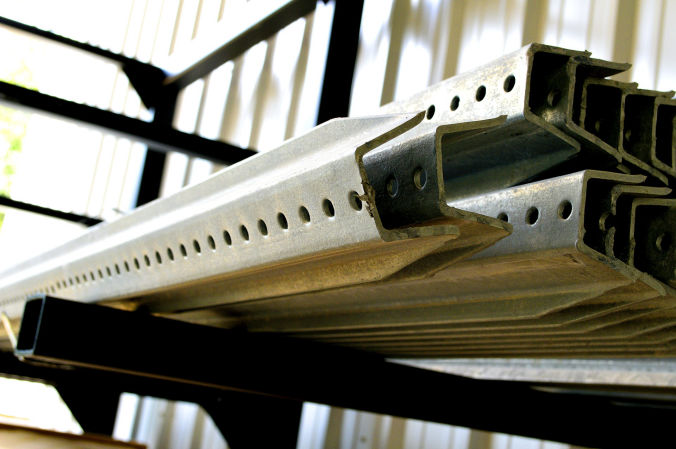

LABORATORY STUDY

Simulating membrane systems on a bench scale with either synthetic or process solutions provide valuable data with regard to membrane selection and performance.

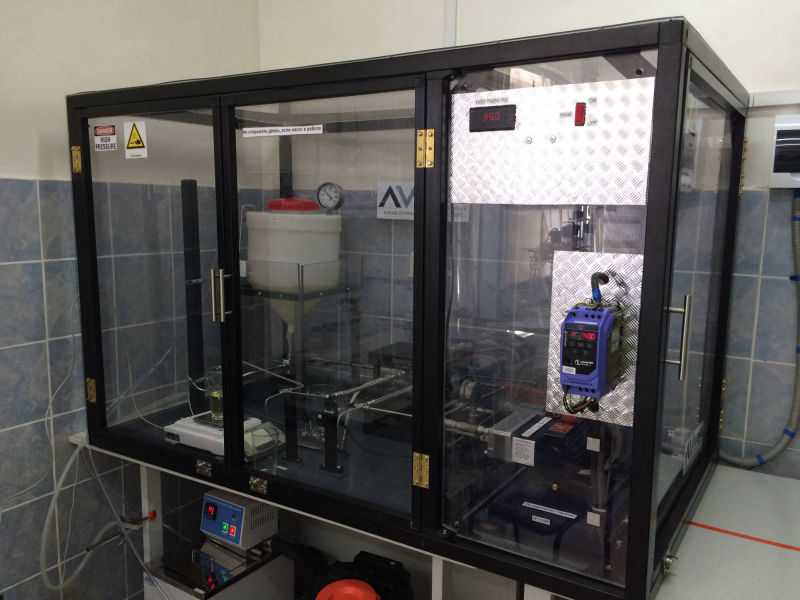

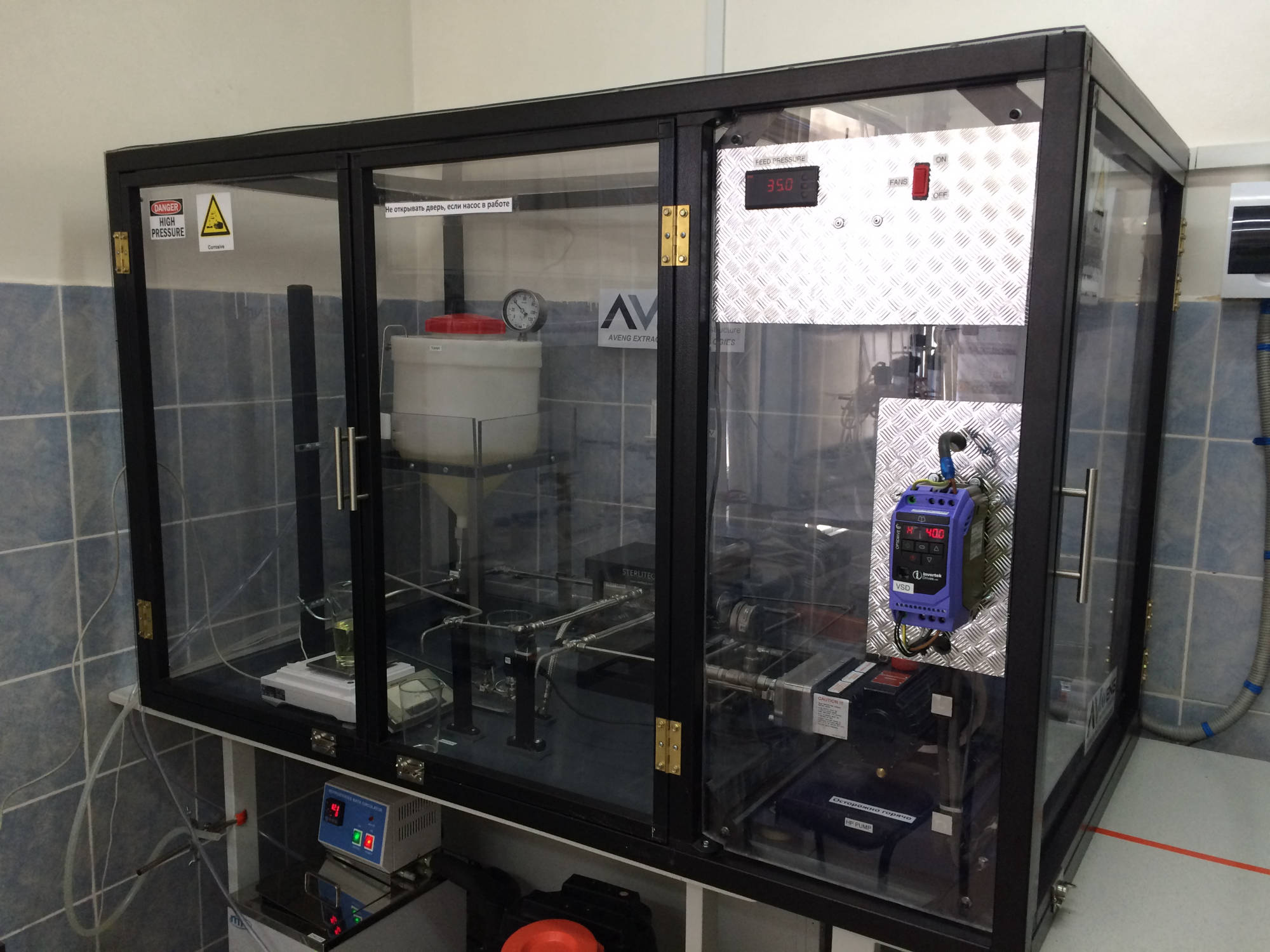

3

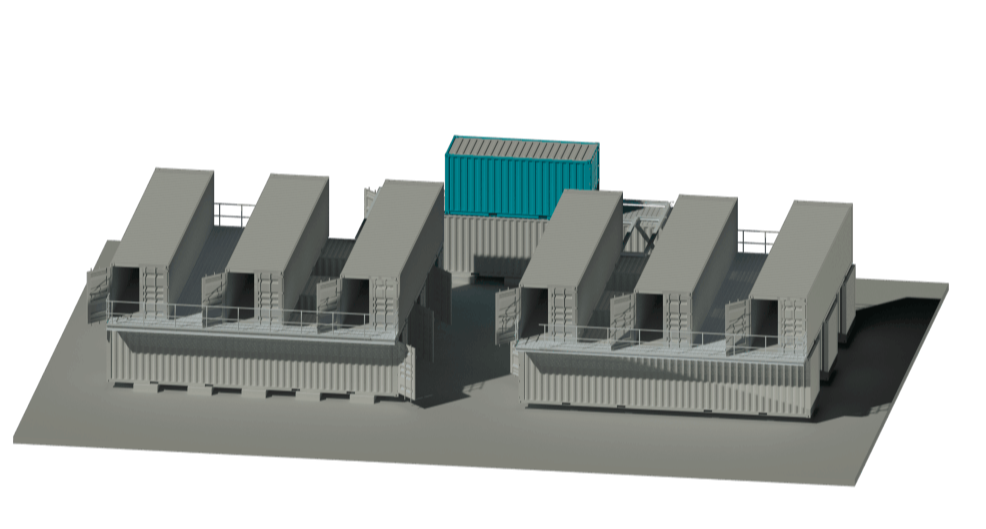

PILOT STUDY

The focus during piloting is to evaluate the membrane parameters under expected operating conditions. Pilot plants are constructed as containerized or skid mounted systems for easy installation and commissioning. The units can be designed to operate in batch mode (where limited sample volumes are available) or continuously with inline and bypass connections. Pilot study data forms the basis for full-scale plant design.